EVA vs Other Materials: Complete Comparison Guide for Custom Cases

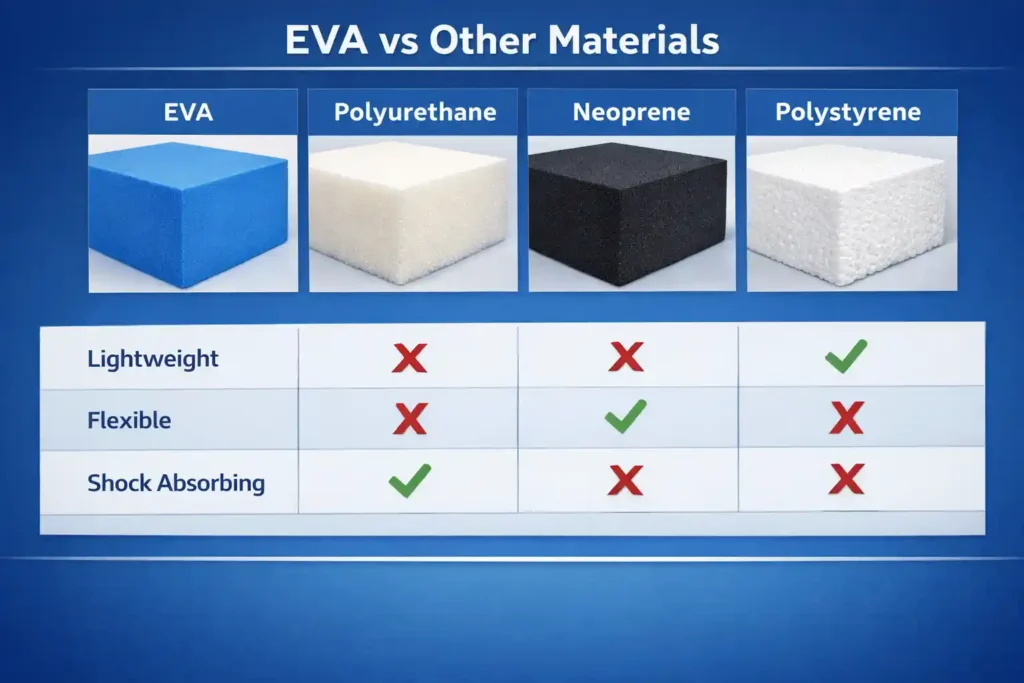

When choosing materials for custom EVA cases, understanding how EVA compares to alternatives is crucial. EVA foam cases have become the industry standard, but polyurethane, neoprene, and polystyrene each offer distinct advantages and disadvantages.

This comprehensive comparison examines EVA against competing materials across cost, durability, protection, sustainability, and customization. Whether you’re sourcing custom EVA cases from a custom EVA case manufacturer or evaluating materials for your project, this guide provides the data you need to make an informed decision.

Key Comparison Points:

- Material properties and performance

- Cost analysis and ROI

- Durability and lifespan

- Environmental impact

- Customization capabilities

- Industry applications

- When to choose each material

Material Properties Comparison

Property | EVA Foam | Polyurethane | Neoprene | Polystyrene |

Density | 20-40 kg/m³ | 30-50 kg/m³ | 25-45 kg/m³ | 15-35 kg/m³ |

Compression Strength | 0.5-2 MPa | 0.8-3 MPa | 0.4-1.5 MPa | 0.2-0.8 MPa |

Temperature Range | -20°C to 60°C | -30°C to 80°C | -40°C to 70°C | -20°C to 50°C |

Flexibility | High | Medium | High | Low |

Durability | 5-10 years | 3-7 years | 4-8 years | 2-4 years |

Cost/kg | $2-4 | $3-6 | $4-8 | $1-2 |

Cost Analysis: EVA vs Alternatives

Custom EVA cases offer the best value proposition:

Initial Material Cost

- EVA: $50-150 per case (depending on size/complexity)

- Polyurethane: $60-180 per case

- Neoprene: $80-200 per case

- Polystyrene: $30-80 per case

Lifecycle Cost (5-year period)

- EVA: $10-30 per year ($50-150 total)

- Polyurethane: $20-50 per year ($100-250 total)

- Neoprene: $20-40 per year ($100-200 total)

- Polystyrene: $15-40 per year ($75-200 total)

Winner: Custom EVA cases provide the best value over time due to durability and reusability.

EVA vs Polyurethane

Polyurethane is often compared to EVA for protective cases.

Advantages of Polyurethane:

- Higher compression strength

- Better temperature resistance

- Excellent cushioning properties

- Suitable for extreme environments

Advantages of EVA:

- Lower cost (20-30% cheaper)

- Better UV resistance

- More sustainable options available

- Easier to customize and print

- Longer lifespan (5-10 years vs 3-7 years)

Best For:

- Choose EVA: Budget-conscious projects, consumer goods, standard environments

- Choose Polyurethane: Extreme temperature applications, military/aerospace

EVA vs Neoprene

Neoprene is popular for water-resistant applications.

Advantages of Neoprene:

- Excellent water resistance

- Superior flexibility

- Thermal insulation properties

- Chemical resistance

Advantages of EVA:

- 50-60% lower cost

- Better impact protection

- Easier manufacturing and customization

- More sustainable alternatives

- Lighter weight

Best For:

- Choose EVA: General protective cases, cost-sensitive applications, custom EVA cases

- Choose Neoprene: Water sports, marine equipment, thermal protection

EVA vs Polystyrene

Polystyrene (Styrofoam) is the budget option.

Advantages of Polystyrene:

- Lowest initial cost

- Good insulation properties

- Lightweight

- Easy to produce

Disadvantages of Polystyrene:

- Fragile and easily damaged

- Poor durability (2-4 years)

- Breaks into microplastics

- Environmental concerns

- Limited customization

Advantages of EVA:

- 5x longer lifespan

- Reusable and durable

- Better environmental profile

- Superior protection

- Professional appearance

Best For:

- Choose EVA: Any professional application requiring durability and protection

Durability and Lifespan Comparison

Custom EVA cases outlast alternatives significantly:

Material | Expected Lifespan | Reuse Cycles | Degradation Rate |

EVA Foam | 5-10 years | 100-500 cycles | 2-3% per year |

Polyurethane | 3-7 years | 50-200 cycles | 5-8% per year |

Neoprene | 4-8 years | 75-250 cycles | 4-6% per year |

Polystyrene | 2-4 years | 10-50 cycles | 15-25% per year |

Result: One custom EVA case replaces 5-10 polystyrene cases over its lifetime.

Environmental Impact Comparison

Sustainability Analysis:

Factor | EVA | Polyurethane | Neoprene | Polystyrene |

Recyclability | High (60-70%) | Medium (30-40%) | Low (10-20%) | Low (5-10%) |

Carbon Footprint | 2.8 kg CO₂ | 4.2 kg CO₂ | 5.1 kg CO₂ | 1.8 kg CO₂ |

Biodegradability | 50-80 years | 200-300 years | 100+ years | 500+ years |

Sustainable Options | Yes (bio-based) | Limited | Rare | No |

Winner: Sustainable EVA packaging offers the best environmental profile.

Customization Capabilities

Custom EVA cases lead in customization flexibility:

EVA Advantages:

- Easy CNC cutting for complex shapes

- Multiple color options (20+ standard colors)

- Excellent printing and branding

- Custom density options

- Flexible design modifications

- Rapid prototyping capability

Polyurethane Limitations:

- More difficult to cut precisely

- Limited color options

- Harder to print on

- Longer modification lead times

Neoprene Limitations:

- Difficult to achieve complex shapes

- Limited color palette

- Printing challenges

- Higher modification costs

Polystyrene Limitations:

- Fragile during customization

- Limited aesthetic options

- Poor printing quality

Industry Applications and Material Selection

Medical Devices:

- Best Choice: EVA (ISO 13485 compliant, hypoallergenic)

- Alternative: Polyurethane

Electronics:

- Best Choice: EVA (excellent shock absorption, static-free options)

- Alternative: Polystyrene (budget option)

Tools and Equipment:

- Best Choice: EVA (durable, customizable)

- Alternative: Polyurethane

Sports and Recreation:

- Best Choice: Neoprene (water-resistant)

- Alternative: EVA (for dry applications)

Luxury Goods:

- Best Choice: EVA (professional appearance, customizable)

- Alternative: Neoprene

Real-World Case Study: Material Comparison

Project: Protective case for professional camera equipment

Polystyrene Solution:

- Initial cost: $35

- Lifespan: 2 years

- Reusable cycles: 20

- Total cost: $35

- Environmental impact: High

EVA Solution:

- Initial cost: $95

- Lifespan: 8 years

- Reusable cycles: 400

- Total cost: $95

- Environmental impact: Low

Result: EVA provides 4x better value and 10x better environmental profile.

How to Choose the Right Material

Decision Framework:

- Budget Constraints

- Lowest cost: Polystyrene

- Best value: EVA

- Premium: Polyurethane

- Durability Requirements

- Short-term: Polystyrene

- Medium-term: Neoprene

- Long-term: EVA or Polyurethane

- Environmental Concerns

- Sustainability priority: EVA (especially bio-based)

- Recyclability: EVA > Polyurethane > Neoprene

- Customization Needs

- Complex shapes: EVA

- Standard designs: Any material

- Branding/printing: EVA

- Application Environment

- Water-resistant: Neoprene

- Extreme temperature: Polyurethane

- Standard conditions: EVA

GADAO's Material Expertise

As a leading EVA case manufacturer, GADAO offers:

- Material Selection Consultation: Expert guidance on best material choice

- Custom EVA Cases: Optimized for your specific application

- Hybrid Solutions: Combining materials for optimal performance

- Sustainable Options: Bio-based and recycled EVA alternatives

- Quality Assurance: All materials tested to international standards

PREGUNTAS FRECUENTES

Q: Is EVA better than polyurethane? A: For most applications, yes. Custom EVA cases offer better value, durability, and customization options. Polyurethane is better only for extreme temperature applications.

Q: Can I recycle my custom EVA case? A: Yes! EVA is 60-70% recyclable. GADAO’s custom EVA cases can be recycled into new products.

Q: Why is EVA more sustainable than polystyrene? A: EVA lasts 5-10 years vs 2-4 years for polystyrene, and is recyclable. One custom EVA case replaces 5-10 polystyrene cases.

Q: What’s the cost difference between materials? A: Initial cost varies, but custom EVA cases offer the best lifetime value due to durability and reusability.

Conclusion and Next Steps

Custom EVA cases provide the optimal balance of cost, durability, customization, and sustainability. Whether you need EVA foam cases for medical devices, electronics, or industrial applications, EVA outperforms alternatives in most scenarios.

Ready to choose the right material for your project?

- Contact GADAO for a free material consultation

- Request samples of different materials

- Get a custom quote for your specific needs